All the necessary equipment to make reliable solar panels is now set up at LVL1. This includes a custom built oven with a vacuum sealing system capable of making panels up to 15x21 inches, but no worries for bigger projects individual panels can be wired together in series or parallel and with the right framing anything is possible. A further break down of this oven and the panel making process is coming in the future. Along with the oven a tile saw has been set up with a 0.015" thick diamond blade. This saw can be used to cut scrap or non-scrap of mono or poly crystalline solar cells into usable custom sizes to fit the needs of various projects. The only other equipment needed to make a panel is a soldering iron, which LVL1 has plenty of. Only some materials for making solar panels will be available the rest will need to be purchased. For more info contact Sam Ellis at srelli02@louisville.edu.

The set up:

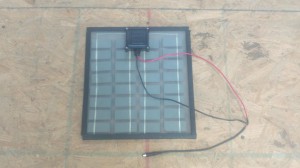

Example of a solar panel made using the equipment followed by a table of its performance characteristics:

Isc: Â 0.4485 A

Voc: Â 16.8 V

PowerMax:Â 5.1 W

Imax:Â 0.3845 A

Vmax:Â 13.28 V

Fill factor:Â 0.6697

% Efficiency:Â 12.36%